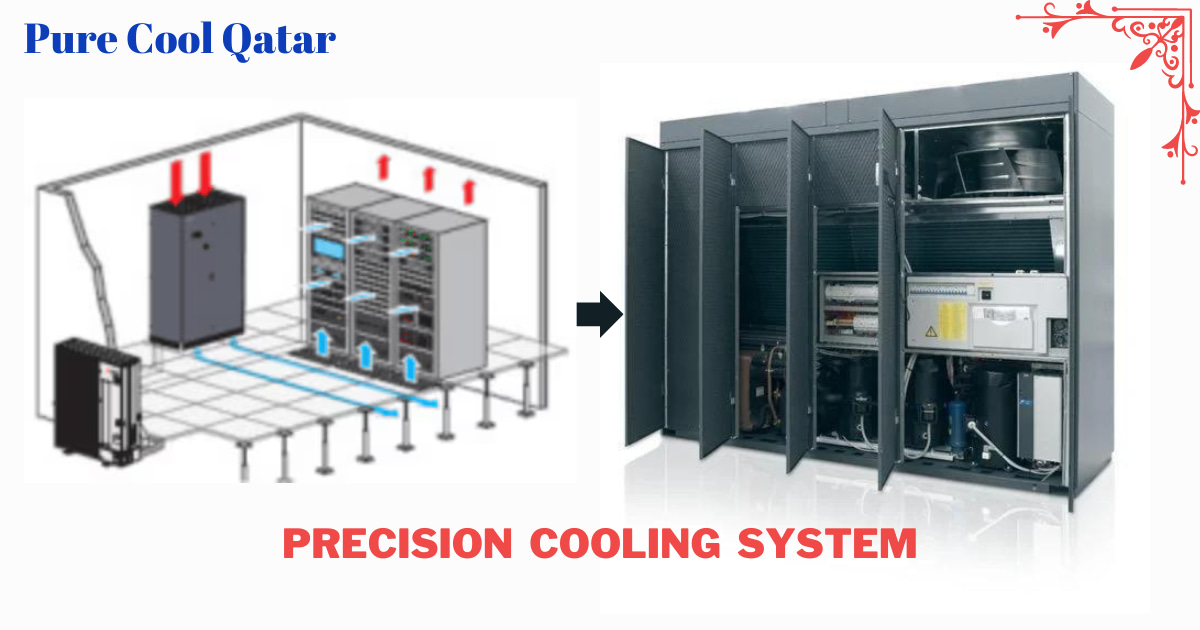

A Precision Cooling System is an air conditioning or cooling technique specifically designed and used to control temperature and humidity to a precision level.

A precision cooling system is more advantageous because it works 24/hrs a day and 365/days a year. It has a heater and humidifier to control the humidity levels as well.

It is used in various cases like data centers, hospitals, laboratories, and UPS rooms.

In this article, I am going to have a discussion of different types of precision cooling systems with their application area.

Types

Three types of precision cooling systems as per Technology are described below:

1. DX / Refrigerant Type DX stands for Direct Expansion. These systems use a refrigerant to cool the air directly in a specific space.

2. Chilled Water Type Chilled water is circulated through a network of pipes to cooling coils located within the space that needs to be cooled in this system.

3. Dual Fluid Type In this system, two independent refrigeration systems are used. If one fails, the other can maintain the freezer until service is arranged.

Features

Let’s explore the key features of a precision cooling system:

1. Targeted Cooling: It focuses on cooling localized areas where heat-generating equipment is located.

2. Temperature and Humidity Control: This system maintains tight temperature and humidity ranges to ensure optimal performance of sensitive machines.

3. Redundancy and Reliability: Precision cooling units often come with redundant components such as dual compressors and fans to ensure continuous operation even if one component fails. So, they can give high reliability.

4. Variable Speed Fans: Precision cooling systems use variable-speed fans that adjust their speed based on cooling demands. This enhances energy efficiency.

5. Hot Aisle/Cold Aisle Configuration: Precision cooling is often combined with a hot aisle/cold aisle layout. That means Cold air is directed toward the front of server racks (cold aisle), while hot air is exhausted from the rear (hot aisle). This separation improves cooling efficiency.

6. Air Filtration: Precision cooling units include high-quality air filters to remove dust and contaminants. Clean air helps maintain equipment reliability and longevity.

7. Modularity and Scalability: Modular precision cooling systems allow for easy expansion so additional cooling units can be added without major disruptions.

8. Leak Detection and Prevention: Some systems have built-in Preventive measures like leak detection sensors to identify refrigerant or water leaks instantly and reduce the risk of damage to equipment.

9. Energy Efficiency: Precision cooling optimizes energy usage by cooling only where needed. These features enhance efficiency.

10. Remote Monitoring and Management: Many precision cooling systems offer remote monitoring and control. So, IT staff can monitor performance, adjust settings, and receive alerts remotely.

Applications

Here are some common applications of precision cooling systems:

1. Data Centers:

Data centers house have various servers and IT equipment that generate heat. Precision cooling ensures optimal operating temperatures for these servers, preventing overheating.

2. Telecommunication:

Telecommunication equipment including network operation centers and base stations, requires precise temperature for proper function.

3. Research Laboratory:

Laboratories, often contain sensitive equipment like microscopes or specialized instruments that require precise temperature and humidity control to ensure optimal operation for accurate results.

4. Medical facilities

Hospitals and clinics sometimes have areas with sensitive equipment, such as MRI machines, that require tightly controlled temperatures for proper functionality and patient safety.

5. Aerospace industry:

In the aerospace industry, precision cooling systems ensure the proper functioning of critical equipment and maintain optimal environmental conditions.

6. Manufacturing:

Many manufacturing processes, such as semiconductor fabrication, require controlled environments with specific temperature and humidity levels to ensure product quality.

7. Food and Beverage Industry:

Precision cooling systems are crucial in food processing and storage facilities to maintain optimal conditions for preserving perishable goods and preventing bacterial growth.

8. Server Rooms and IT Closets:

Even smaller-scale IT environments, like server rooms in office buildings or IT closets, benefit from precision cooling to prevent equipment overheating and ensure uninterrupted operation.

9. Art Conservation:

Museums, galleries, and archives use precision cooling systems to maintain stable environmental conditions to preserve artwork, historical documents, and artifacts.

10. Greenhouses:

greenhouse cultivation relies on precision cooling to regulate temperature and humidity levels for optimal plant growth and crop yield.

Working system

The core functionality of a precision cooling system relies on a refrigerant cycle similar to a regular air conditioner but with a focus on precise control. Here’s a closer look at the working system:

- Monitoring and Analyzing:

The system continuously monitors temperature and humidity within the controlled space using sensors. Advanced control algorithms analyze the sensor data and determine the required cooling output.

- Compressor and Refrigerant System:

A high-quality compressor squeezes refrigerant gas, raising its pressure and temperature.

- Evaporator and Cooling Cycle:

The hot, high-pressure gas travels through the evaporator coils. Air from the hot aisle is drawn over the evaporator coils. The refrigerant absorbs heat from the air, causing it to cool and condense back into a liquid state. The cooled air is then circulated back to the equipment.

- Cooling Coils and Air Circulation:

The chilled liquid refrigerant enters the cooling coils. Cool air from the evaporator is then blown across these coils, thus reducing its temperature. Fans circulate the cooled air throughout the data center or server room.

- Dehumidification (Optional):

Some systems may include dehumidification features to manage moisture levels if needed. This can involve processes like condensation or desiccant dehumidification.

Liebert Precision Cooling System

Liebert is a brand of Vertiv that provides various products for Precision Cooling Systems. These products effectively dissipate excess heat generated by equipment such as computer servers,

Types of Liebert Cooling System products:

Some of Liebert’s Cooling Systems are listed below:

- Room Cooling Systems: These systems regulate the temperature throughout the entire data center.

- In-Row Cooling Systems: These systems are installed in rows between servers and directly cool them.

- Rack Cooling Systems: These systems are placed within server racks and directly cool the servers.

- Liquid Cooling Systems: These systems use water or other liquid substances to remove heat from servers top of Form

Advantages of Liebert Precision Cooling System:

This system offers several advantages:

- Enhances equipment efficiency in data centers by maintaining appropriate temperatures,

- Effective temperature control helps reduce electricity consumption, thus it reduces operational costs.

- Mitigates environmental impact by effectively controlling heat.

Liebert Cooling System:

Some of Liebert’s Cooling Systems are listed below with a brief discussion:

Liebert CRV Air Cooling System

The Liebert CRV is a precision data center cooling solution, integrated within a row of data center racks. It can precisely deliver highly efficient cooling in the row where it’s needed. The system is available in multiple options, providing flexibility for any installation.

Key Benefits

- Designed with a minimal footprint to save valuable floorspace in edge applications, server rooms, and small data centers

- Highly efficient, scalable cooling capacity provides lower energy consumption and operational costs

- Adjustable air discharge baffles improve cold air distribution, eliminating hot spots in the row

- Simultaneous top and bottom connections allow for greater flexibility during installation for various building configurations

- Multiple monitoring protocols and multi-unit teamwork allow users to stay informed of system conditions at all times

Best Suited For:

- Banking, Financial, and Insurance

- Data Center/Colocation/Hosting

- Education

- Healthcare

- Retail and Wholesale

Liebert DS Direct Expansion Cooling System

As the world’s most flexible and reliable direct expansion data center cooling system, the Liebert DS improves data center efficiency and protection. The system uses the industry’s most advanced thermal controls and features a modular design, multiple compressor options, and easy service access.

Key Benefits

- Provides assurances of product efficiency and capacity performance.

- Ensures product compliance with ISO Guide 65 and industry technical standards.

- Reduces project implementation times and costs by eliminating costly and time-consuming third-party testing.

- Validates the ratings and performance software used by Vertiv to estimate the performance of standard and non-standard product designs.

- Provides access to the real-time AHRI database of products, based on the Datacom 1360 certification program, ratings, and manufacturers

Best Suited For:

- Banking, Financial and Insurance

- Broadcast and Entertainment

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Ending

After months of careful planning, exact testing, and countless adjustments, the Precision cooling system was finally operating at peak efficiency. Its advanced algorithms seamlessly regulated airflow and temperature, ensuring optimal conditions for the sensitive equipment.